Safe chemical storage is very important for industries in the UAE. When chemicals are stored the wrong way, they can cause fires, leaks, health issues, and serious accidents. Proper storage helps protect workers, property, and the environment.

- Tips To Prevent Workplace Hazards in UAE Chemical Storage

- 1. Proper Chemical Labeling and Identification

- 2. Dedicated Storage Areas

- 3. Using Plastic Pallets for Storage

- 4. Proper Ventilation in Storage Areas

- 5. Spill Control and Containment Systems

- 6. Training Workers on Chemical Safety

- 7. Regular Safety Inspections and Maintenance

- Conclusion

Best practices to prevent chemical storage hazards in the UAE include clear labeling, safe storage areas, strong pallets, proper ventilation, spill control systems, trained staff, and regular safety checks.

These practices help reduce risks and support safety rules. Many companies also work with a reliable supplier in the UAE to improve storage safety.

Tips To Prevent Workplace Hazards in UAE Chemical Storage

Industries in the United Arab Emirates handle many types of chemicals every day. These chemicals may be flammable, toxic, or reactive. To prevent these hazards, here are the best practices you should follow:

1. Proper Chemical Labeling and Identification

Clear labeling is the first step in safe storage. Every container should have the correct name, hazard signs, and handling instructions. Labels help workers quickly understand risks and take safe actions.

Without labels, workers may mix chemicals or handle them in unsafe ways. Color codes and warning signs also help during emergencies. Proper labeling reduces confusion and supports faster response during spills or leaks. This simple step can prevent serious workplace injuries.

2. Dedicated Storage Areas

Chemicals should be stored in separate areas away from regular workspaces. These storage rooms must be clean, dry, and secure. Access should be limited to trained staff only. Separate storage helps avoid contact with heat, food, or other materials.

Storage areas should also match the type of chemical, such as flammable or corrosive items. Dedicated spaces reduce the chance of accidents and help keep chemicals under control at all times.

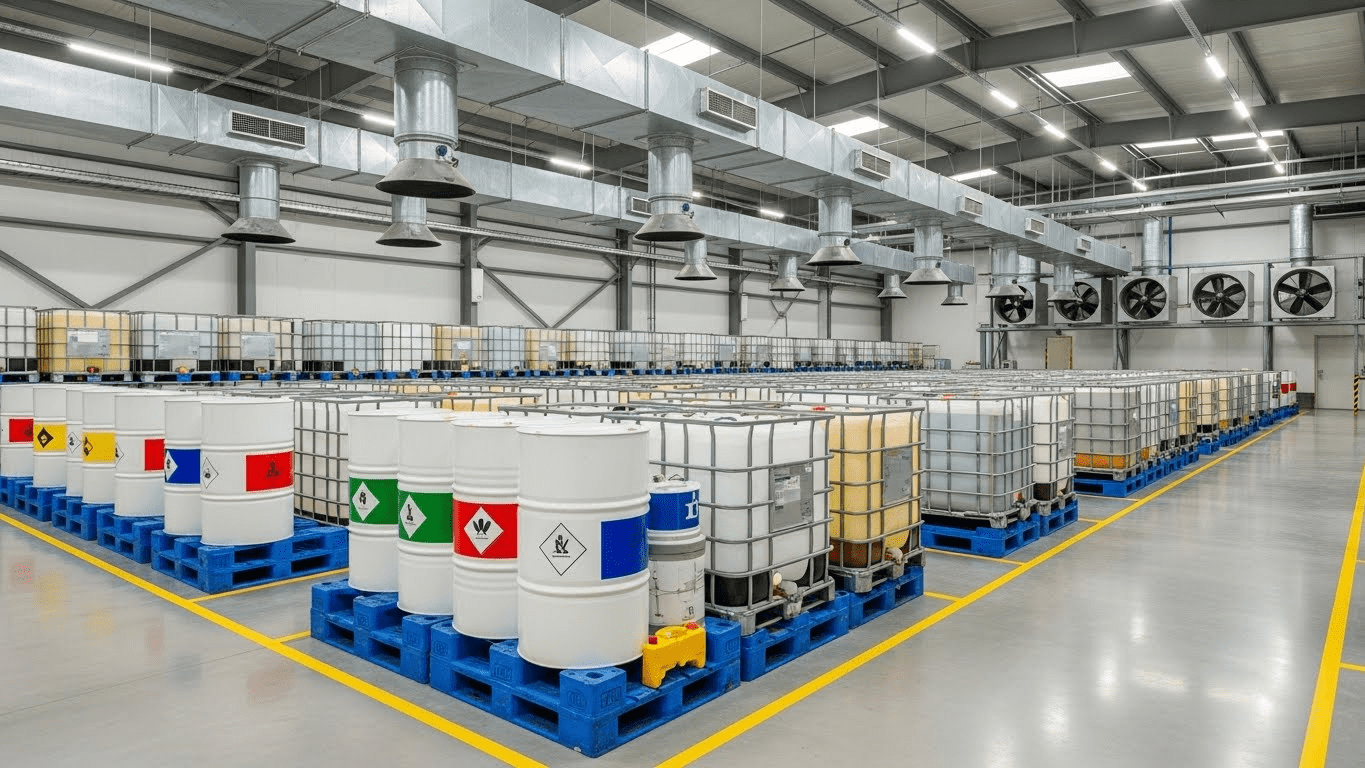

3. Using Plastic Pallets for Storage

Plastic pallets play an important role in chemical storage safety. They do not absorb liquids and are easy to clean after spills. Unlike wooden pallets, plastic pallets do not crack or hold chemicals.

Many industries choose pallets from a trusted plastic pallet supplier in the UAE for safe storage. These pallets support heavy loads and resist chemical damage. Using strong pallets also improves warehouse safety and reduces slip risks during handling.

4. Proper Ventilation in Storage Areas

Good ventilation helps control fumes and heat in chemical storage rooms. Some chemicals release harmful gases that can build up in closed spaces. Ventilation systems remove these fumes and bring in fresh air.

This protects workers from breathing problems and reduces fire risks. Fans, vents, and exhaust systems are commonly used. Proper airflow also helps maintain stable storage conditions. Good ventilation is a key part of chemical safety in the United Arab Emirates industries.

5. Spill Control and Containment Systems

Spills can happen even with careful handling. Spill control systems help limit damage when leaks occur. These systems include spill trays, absorbent pads, and containment pallets. They stop chemicals from spreading across floors or entering drains.

Quick spill control reduces injury risks and protects the environment. Every storage area should have spill kits ready for use. Workers should know how to use them correctly during emergencies.

6. Training Workers on Chemical Safety

Training helps workers understand chemical risks and safe handling methods. Employees should know how to read labels, use safety gear, and respond to spills. Regular training sessions keep safety knowledge fresh.

Trained workers make fewer mistakes and react faster during incidents. Training also builds a safety-first culture in the workplace. In the UAE, proper training supports compliance with safety laws and industry standards.

7. Regular Safety Inspections and Maintenance

Regular inspections help identify storage issues early. Safety checks include checking containers, pallets, shelves, and ventilation systems. Damaged containers should be replaced quickly. Inspections also help ensure chemicals are stored in the right areas.

Maintenance keeps safety systems working properly. By fixing small issues early, industries can avoid major accidents. Regular checks support long-term safety and smooth operations.

Conclusion

Safe chemical storage is a key part of workplace safety in the UAE.

Preventing Workplace Hazards: Chemical depot best practices for UAE industries helps protect workers, reduce accidents, and support safety laws. Proper labeling, storage areas, pallets, ventilation, spill control, training, and inspections all work together.

When companies utilize robust storage tools and adhere to best practices, they foster safer workplaces. Choosing quality equipment from a trusted plastic pallet supplier in the UAE also supports safe and reliable storage of chemicals. These steps help industries grow while keeping people and property safe.